Product introduction

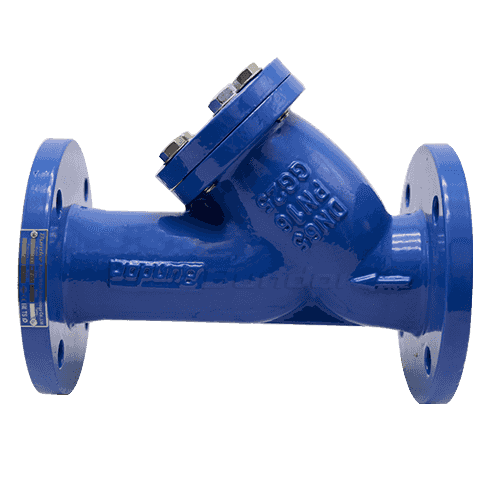

Y-type filter is a indispensable device in transmission pipeline system, usually installed inlet in pressure reducing valve, pressure relief valve, water valve and other device, the valve is used to remove impurities in order to protect the valve and equipment in normal use.

Size:1/2"--18"

Material: cast iron,WCB,stainless steel 304(CF8)

Pressure: Class 150

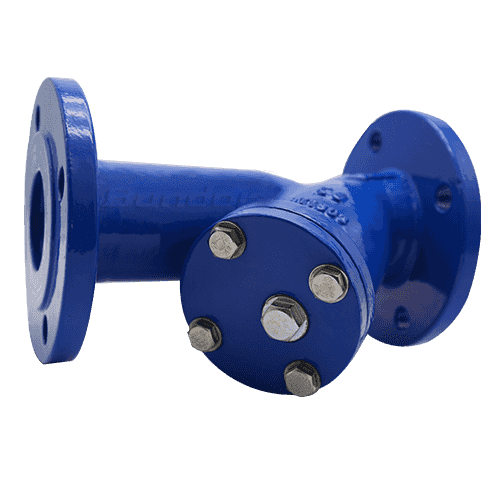

Connection:Flange

Temperature range: ≤250℃

Applicable Media:water,oil

Adoptive Standards

Valve Design: DIN3352

Face To Face: DIN3202, BS2080

Flange Drilling: DIN2531/2/3, BS4504

Product Advantage

1.Strainer body meets applicable DIN standard,large inner space,reduce pressure drop.

2.Ductile iron body material,can't broken by transfer and install.

3.Streamline design for low pressure drop.

4.Epoxy coating,prevent corrosion and rust.

5.There is pressure tap leave on the bonnet,can install pressure measuring device to test pipe pressure.

6.The drain plug can be changed to ball valve according to customer's request.The ball valve can connect with drain pipe.No need to assemble the bonnet when drain contamination with pressure.

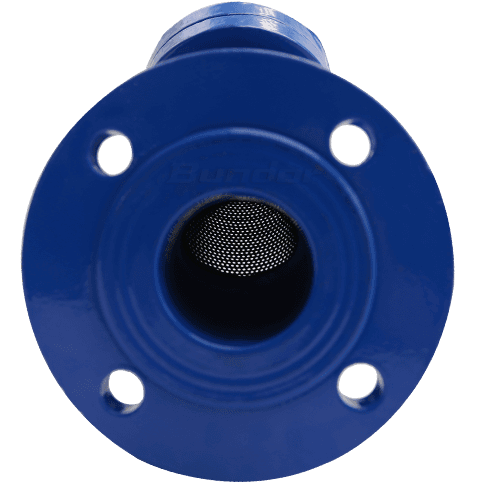

7.Can supply different precision filter according to different customer's request,clean easily.

8.Dimension of inner cavity inlet is 1.2-1.3 time larger than size,the screen length is 1.5 time than normal,improve flow,Extended cleaning cycle.

9.The screen is install by 45 degree,the mesh area is 3-4 times larger than nominal diameter area, lower flow resistance,larger flow.

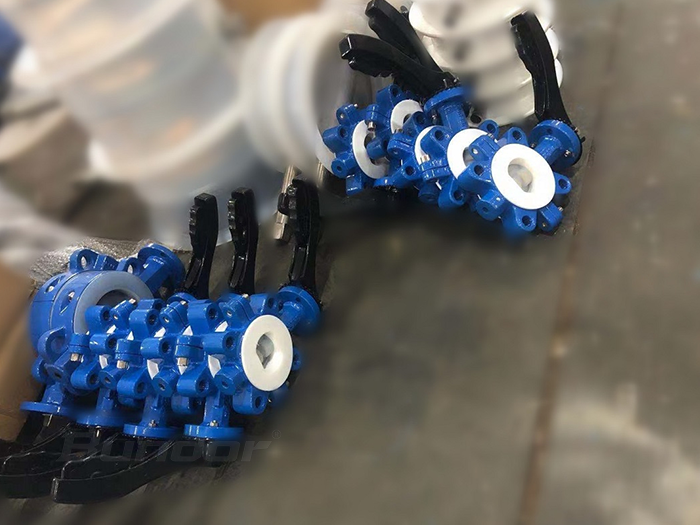

10.Since founded in 1994, own production, sales, design,aftersale, we are your strong support when sale and use.

Standard Test

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.