Introduction

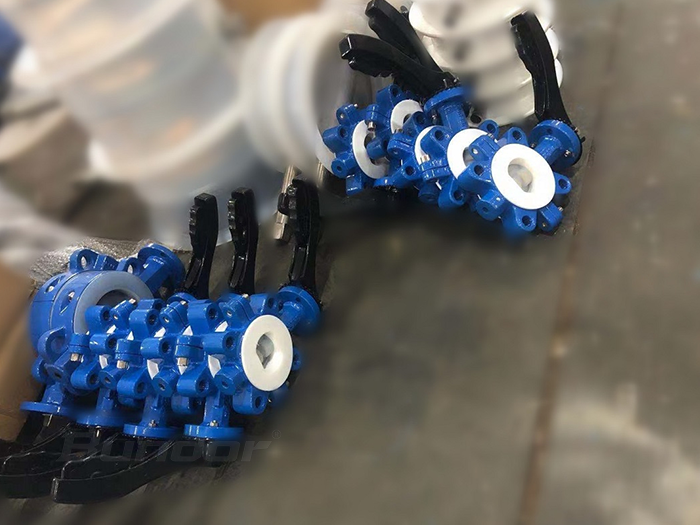

Size: DN25-DN300

Pressure: PN16

Working temperature: -20℃~150℃

Suitable medium: Corrosive media

Application : Petroleum, chemical, pharmaceutical, environmental protection, etc.

Product advantages:

1. The valve body is casted precisely , material and mechanical properties meet the standards;

2. FEP lining is used, which has extremely high chemical stability;

3. The valve body is streamlined design, with smaller flow resistance and larger flow area;

4. Each valve is pressure tested according to national standards before leaving the factory;

5. It adopts powder epoxy resin electrostatic coating, which can effectively prevent corrosion and rust caused by the contact between the valve body and the medium while improving the adhesion, and the spray thickness is more than 250um.

Parameters

| Optional material | Name | Body | Lined |

| Y strainer | WCB/CF3M/CF8/ CF8M | FEP/PFA/PTFE |

| Parameter Information: | ||||||||

| 1. Executive standard: |

| Name | Design and manufacture | Face to face Length | Pressure Test | End Flange |

| Reference standard | SH/T 3411 | GB/T 12221 | GB/T 13927 | HG/T 20592 |

| 2. Material of Main Parts: |

| Name | 1-Body | 2-Screen | 3-Gasket |

| Material | WCB+F46 | F46 | PTFE |

| 3. Dimensions: |

| SIZE | ||||||

| DN | NPS | L | H | ΦD | ΦK | n-Φd |

| 25 | 1'' | 165 | 115 | 115 | 85 | 4-14 |

| 32 | 1 1/4'' | 185 | 115 | 140 | 100 | 4-18 |

| 40 | 1 1/2'' | 200 | 145 | 150 | 110 | 4-18 |

| 50 | 2'' | 230 | 165 | 165 | 125 | 4-18 |

| 65 | 2 1/2'' | 295 | 175 | 185 | 145 | 8-18 |

| 80 | 3'' | 315 | 205 | 200 | 160 | 8-18 |

| 100 | 4'' | 355 | 230 | 220 | 180 | 8-18 |

| 125 | 5'' | 405 | 285 | 250 | 210 | 8-18 |

| 150 | 6'' | 480 | 315 | 285 | 240 | 8-22 |

| 200 | 8'' | 605 | 400 | 340 | 295 | 12-22 |

| 250 | 10'' | 680 | 430 | 405 | 355 | 12-26 |

| 300 | 12'' | 780 | 470 | 460 | 410 | 12-26 |