Introduction

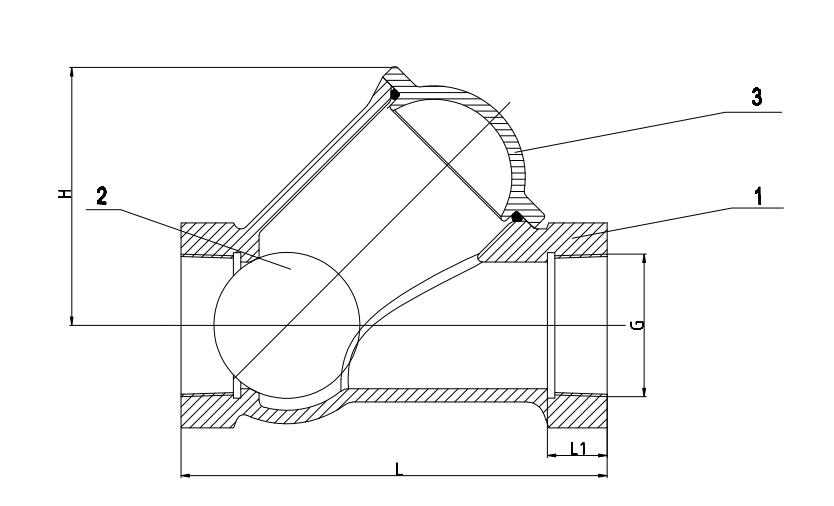

The threaded ball check valve is also called a slide ball check valve. It uses a rubber-covered rolling ball as the valve core. Under the action of the medium, it can roll up and down on the integral slide of the valve body to open or close the valve. It has good sealing performance and does not produce water hammer. The valve body adopts a full water flow channel, with a large flow rate and low resistance. It can be used for cold water, hot water, industrial and domestic sewage pipe networks, and the medium temperature is 0-80℃. It can be installed at the outlet of the water pump to prevent backflow and water hammer from damaging the pump.

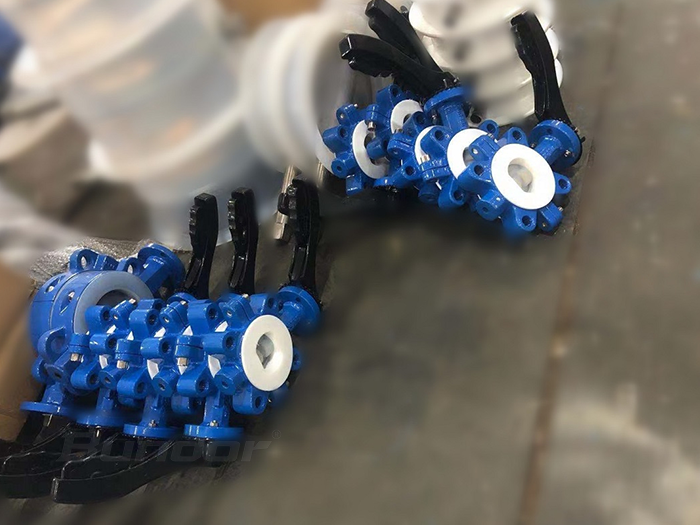

Product Advantages

1. The valve body has a spheroidization rate of level 3, a tensile strength of 450Mpa, and an elongation greater than 10%

2. The valve body is solid and heavy, and the wall thickness meets the standard

3. The ball is coated with EPDM, and the rubber content meets the standard to ensure the material quality

4. Stainless steel bolts are used, which have high strength and strong corrosion resistance

5. The valve body is electrostatically coated with powder epoxy resin, and the spraying thickness reaches 250μm

6. Each valve is subjected to double-layer pressure testing of the shell and seal according to the standard before leaving the factory

Parameters

| Name | Design and Manufacture | Thread Type Pressure | Test Standard | |

| Reference Standard | BS EN12334 | G thread/ BSP thread/ NPT thread | BS EN12266 | |

| Main parts information: | ||||

| Name | 1- Valve body | 2- Ball | 3- Bonnet | |

| Material and Description | DI | Steel+EPDM | DI | |

| Dimension information: | ||||

| SIZE | ||||

| DN | G | L | H | L1 |

| 25 | 1'' | 125 | 76 | 16.8 |

| 32 | 1 1/4'' | 132 | 76 | 20 |

| 40 | 1 1/2'' | 145 | 89 | 20 |

| 50 | 2'' | 175 | 113 | 21.7 |

| 65 | 2 1/2'' | 200 | 142 | 26.7 |

| 80 | 3'' | 243 | 156 | 29.8 |