Introduction

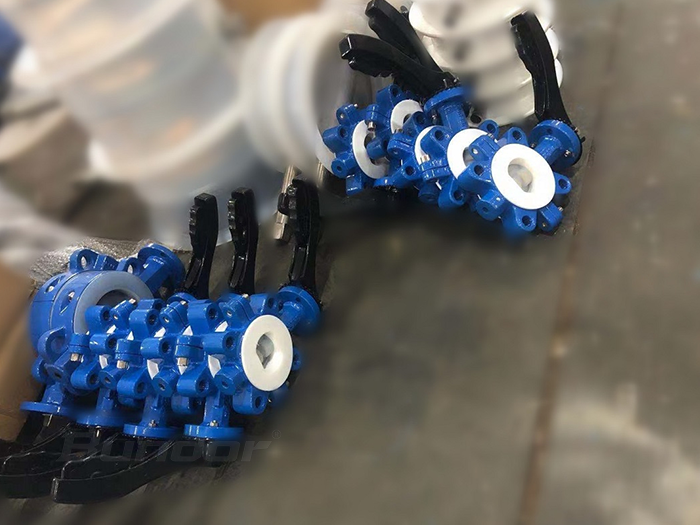

Forged steel check valve is a valve that automatically opens and closes the valve disc depending on the flow of the medium itself to prevent the backflow of the medium. It is made of forged steel and has high strength and pressure-bearing capacity. The material is diverse to adapt to different environments. It has the characteristics of high pressure resistance, corrosion resistance, and high temperature resistance. It has a simple structure and is easy to use. It is widely used in many industries such as petroleum, chemical, and natural gas.

Product Advantages

1. The material is made of high-quality forged steel, and the chemical composition and mechanical properties meet national standards. Material reports can be provided.

2. The internal parts are processed by CNC machine tools, with precise matching, interchangeable parts, and smooth and beautiful appearance.

3. The sealing surface is plasma surfacing to increase the wear resistance of the valve, and the hardness meets national standards.

4. The cleanliness of the inner cavity meets the JB/T7748 standard and meets the long-term storage requirements of the valve.

5. Each valve is subjected to double-layer pressure testing of the shell and seal in accordance with national standards before leaving the factory.

Parameters

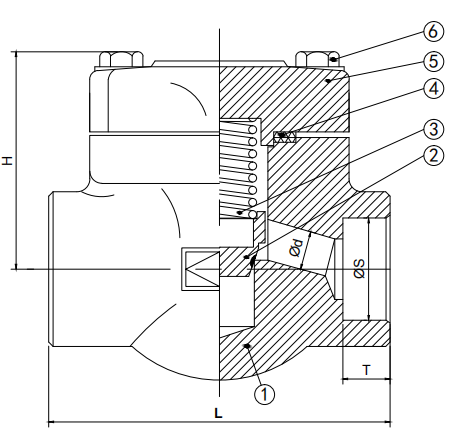

| Parameter information: | |||||||

| 1. Valve implementation standards: | |||||||

| Name | Design and manufacturing | Connection Standards | Structure length | Pressure test standard | |||

| Reference Standards | API 602 | ASME B16.11 | ASME B16.10 | API 598 | |||

| 2. Main parts information: | |||||||

| Name | Valve body | Valve Seat | Valve disc | spring | |||

| Material and Description | A105 | 13Cr | A105 | 304 | |||

| 3. Size information: | |||||||

| Nominal size | |||||||

| DN | NPS(Inch) | L | H | Φd | T | ||

| 15 | 1/2'' | 79 | 55 | 10.5 | 10 | ||

| 20 | 3/4'' | 92 | 58 | 13 | 13 | ||

| 25 | 1'' | 111 | 78 | 18 | 13 | ||

| 32 | 1 1/4'' | 120 | 88 | 23 | 13 | ||

| 40 | 1 1/2'' | 152 | 96 | 28 | 13 | ||

| 50 | 2'' | 172 | 108 | 36 | 15 | ||