Introduction

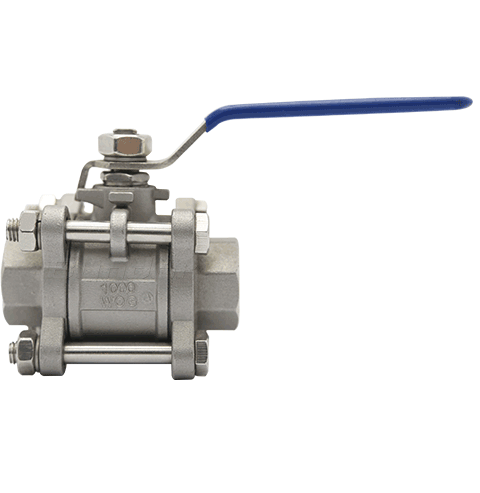

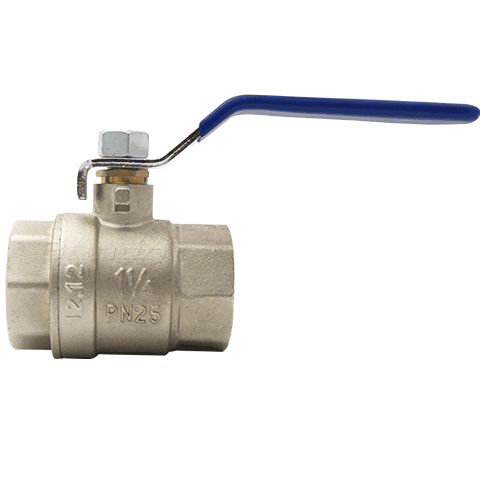

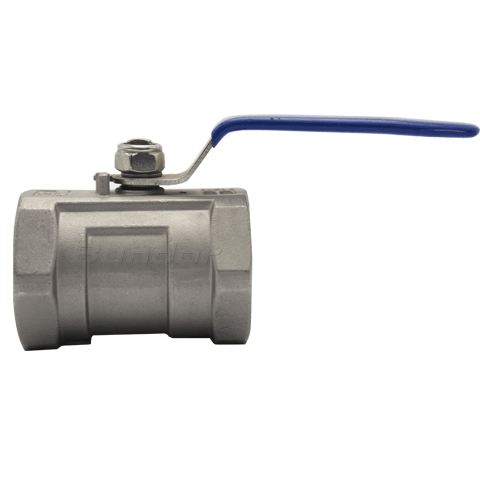

The forged steel ball valve works by rotating the valve stem and is made of forged steel. It has high strength and pressure-bearing capacity. The material is diverse and can adapt to different environments. It has the characteristics of high pressure resistance, corrosion resistance, and high temperature resistance. It has a simple structure and is easy to operate. It is widely used in many industries such as petroleum, chemical industry, and natural gas.

Product advantages

1. The material is made of high-quality forged steel, and the chemical composition and mechanical properties meet the national standards. Material reports can be provided.

2. Anti-blowout design for valve stem, anti-static structure for valve

3. The chemical composition and roughness of the valve stem material meet the national standard requirements, and the surface is treated with corrosion resistance nitriding or tempering to ensure the mechanical properties of the valve stem

4. The dimensional tolerance meets the national standard GB/T1800-1800.3, and the spare parts are interchangeable

5. Before the whole machine is assembled, it is cleaned with kerosene and anti-rust oil by high-pressure jetting. After the pressure test, the test medium is removed and anti-rust oil is sprayed. The cleanliness of the inner cavity meets the JB/T7748 standard

6. Each valve is tested for double-layer pressure of the shell and seal in accordance with national standards before leaving the factory

Parameters

| 1. Valve Implementation Standards: | |||||||

| Name | Design and Manufacturing | Connection Standards | Structure Length | Pressure Test Standard | |||

| Reference Standards | API 608 | ASME B16.11 ASME B1.20.1 |

ASME B16.10 | API 598 | |||

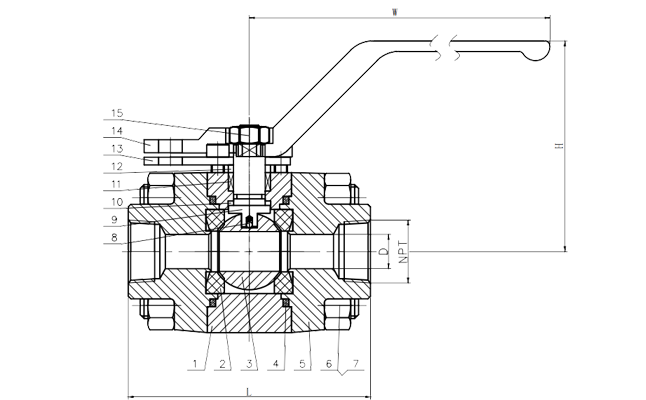

| 2. Main Parts Information: | |||||||

| Name | 1-Valve body | 2-Valve Seat | 3-Sphere | 9-Valve Stem | |||

| Material and Description | F304 | PTFE | F304 | 2Cr13 | |||

| 3. Size Information: | |||||||

| Nominal Size | |||||||

| DN | NPS(Inch) | L | D | H | |||

| 15 | 1/2'' | 92 | 13 | 66 | |||

| 20 | 3/4'' | 112 | 19 | 72 | |||

| 25 | 1'' | 126 | 24 | 100 | |||

| 32 | 1 1/4'' | 129 | 30 | 105 | |||

| 40 | 1 1/2'' | 152 | 38 | 112 | |||

| 50 | 2'' | 176 | 49 | 122 | |||