Introduction

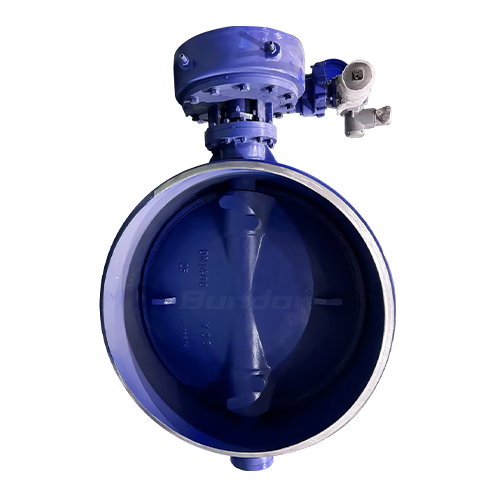

Welded hard seal butterfly valve adopts three-eccentric multi-layer metal hard seal structure and is widely used in industrial pipelines such as metallurgy, electric power, petrochemical, water supply and drainage, municipal construction, etc. to adjust flow and cut off fluid. It has the dual advantages of metal hard seal and elastic seal. It has excellent sealing performance under low and high temperature conditions, and is corrosion-resistant and has long service life.

Product Advantages

1. The valve body is a precision casting valve body or a whole seamless steel pipe, with material performance up to standard and fine appearance;

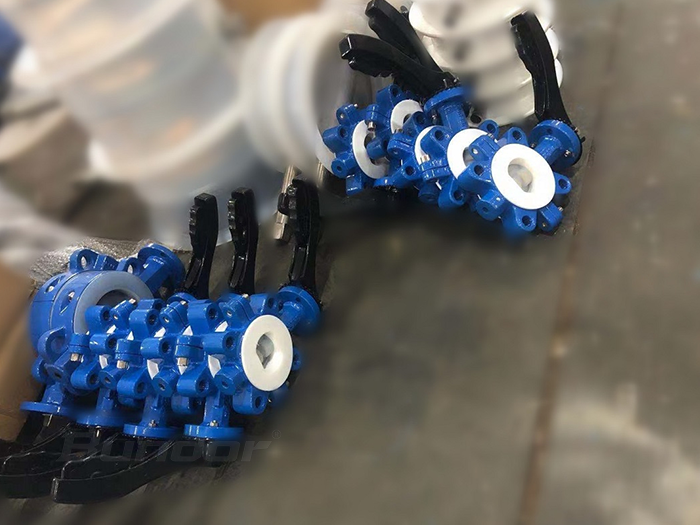

2. The butterfly plate is processed by CNC precision machine tools with high precision

3. The sealing ring is a soft and hard multi-layer stacked metal ring, which has the dual advantages of metal and elastic sealing, ensuring excellent sealing performance in high and low temperature environments

4. The valve stem is made of stainless steel 420, and the strength of the valve stem is doubled after quenching and tempering

5. The worm gear adjusting screw of each product is equipped with a protective nut to protect the adjusting screw from damage

6. Each valve is tested for double-layer pressure of the shell and seal in accordance with national standards before leaving the factory

7. Bidirectional sealing and full metal hard-to-hard sealing can be made according to customer working conditions

Parameters

| Parameter Information: | |||||||

| 1. Valve Implementation Standards: | |||||||

| Name | Design and Manufacturing | Structure Length | Pressure Test Standard | Groove Connection Size | |||

| Reference Standards | JB/T 8527 | GB/T 12221 | GB/T 13927 | GB/T 12224 | |||

| 2. Main Parts Information: | |||||||

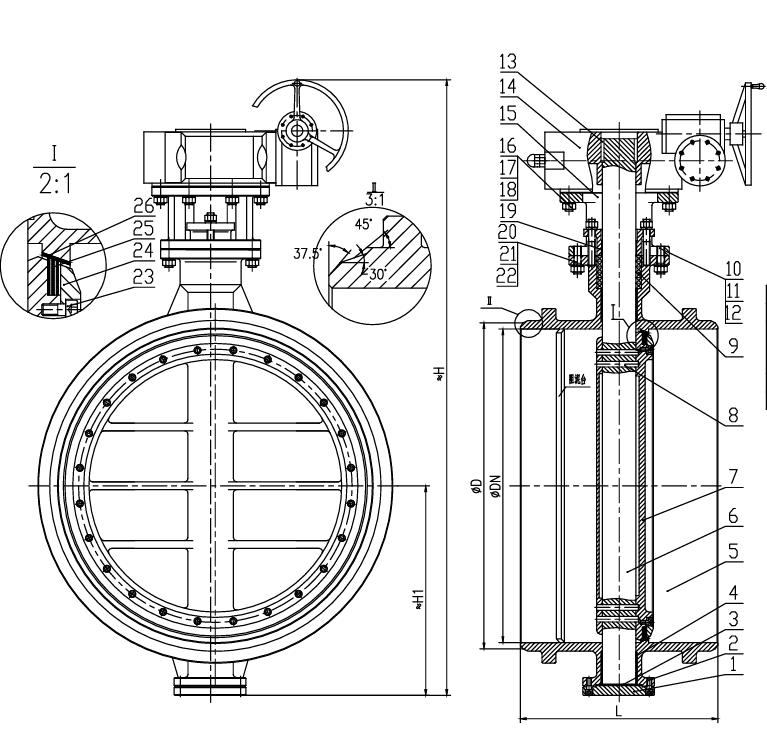

| Name | 5-Valve Body | 25-Seal Ring | 7-Butterfly Plate | 6-Valve Stem | |||

| Material and Description | WCB | 430+graphite | WCB | 2Cr13 | |||

| 3. Size Information: | |||||||

| Nominal Size | PN25 | ||||||

| DN | NPS(Inch) | L | D | H1 | H | ||

| 100 | 4'' | 190 | 110 | 100 | 380 | ||

| 125 | 5'' | 200 | 135 | 110 | 400 | ||

| 150 | 6'' | 210 | 161 | 130 | 450 | ||

| 200 | 8'' | 230 | 222 | 210 | 550 | ||

| 250 | 10'' | 250 | 278 | 240 | 630 | ||

| 300 | 12'' | 270 | 330 | 280 | 720 | ||

| 350 | 14'' | 290 | 382 | 310 | 820 | ||

| 400 | 16'' | 310 | 432 | 350 | 920 | ||

| 450 | 18'' | 330 | 484 | 390 | 1060 | ||

| 500 | 20'' | 350 | 535 | 430 | 1130 | ||

| 600 | 24'' | 390 | 636 | 500 | 1280 | ||

| 700 | 28'' | 430 | 726 | 570 | 1480 | ||

| 800 | 32'' | 470 | 826 | 630 | 1610 | ||

| 900 | 36'' | 510 | 926 | 690 | 1860 | ||

| 1000 | 40'' | 550 | 1028 | 760 | 2040 | ||

| 1200 | 48'' | 630 | 1228 | 850 | 2240 | ||