Features:

Applicable medium:Water、Weak corrosive medium etc.

Suitable temperature:0-325℃

Application field:Water treatment, petrochemical, food and medicine, electric energy, metallurgy, etc.

Product advantages:

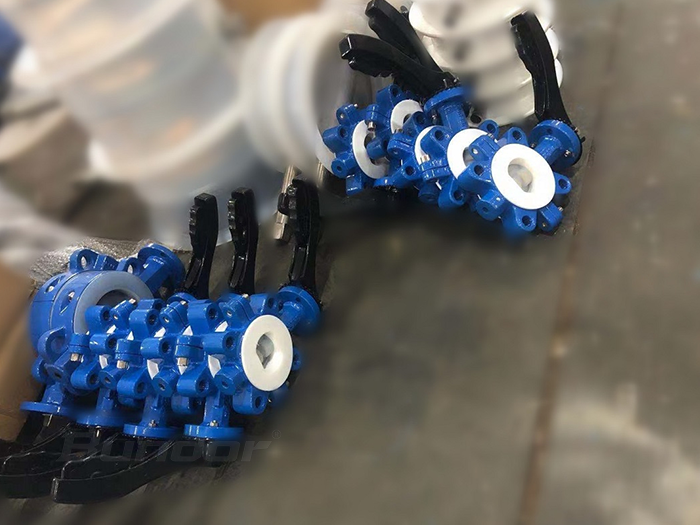

1. Precision casting valve body, smooth appearance, 2 times shot blasting after appearance processing, no trachoma.

2. CNC lathe processing of internal parts, guaranteed accuracy.

3. Heavy type valve body.

4. Inverted seal treatment of contact surface between bonnet and stem to avoid leakage.

5. The corrosion resistance was improved due to the body adopt pickling passivation treatment.

6. Each valve will be inspected for shell and seal pressure before leaving factory.