Introduction

The ball and valve seat are paired and ground, and all sealing areas of the entire sealing surface of the ball valve are precision ground. Suitable for high temperature and high pressure water, steam, oil, coal, fibers, thick and corrosive media, and media with particles.

Product Advantages

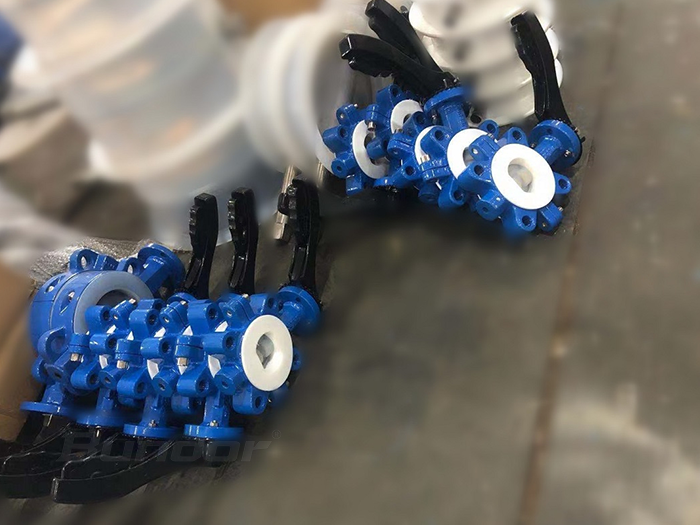

1. The valve body is a precision casting valve body, with secondary shot blasting treatment; Fine appearance and material conforms to standard

2. Valve trims are processed through CNC precision equipment to ensure accuracy

3. Blow-out proof stem

4. SS304 Ball Nitrided or Chrome Plated

5. The valve seat is sprayed with nickel alloy and the hardness of the sealing surface is reliable

6. Each valve body is subjected to surface pickling and passivation treatment, so that the surface of the casting has a uniform silver-white bright color, maintains metallic luster, and improves corrosion resistance.

7. Each valve is tested for shell and seal pressure in accordance with national standards before leaving our factory

Parameters

| Name | Design and manufacture | Face to face Length | Pressure Test | End Flange |

| Reference standard | GB/T 12237 | GB/T 12221 | GB/T 13927 | HG/T 20592 |

| Name | 1-Body | 6-Ball | 7-Seat |

| Material | CF8 | 304 Nitrided | 304+NI55 |

| DN | NPS | L | ΦD | ΦD1 | ΦD2 | n-Φd |

| 15 | 1/2'' | 130 | 95 | 65 | 45 | 4-14 |

| 20 | 3/4'' | 140 | 105 | 75 | 58 | 4-14 |

| 25 | 1'' | 150 | 115 | 85 | 68 | 4-14 |

| 32 | 1 1/4'' | 165 | 140 | 100 | 78 | 4-18 |

| 40 | 1 1/2'' | 180 | 150 | 110 | 88 | 4-18 |

| 50 | 2'' | 200 | 165 | 125 | 100 | 4-18 |

| 65 | 2 1/2'' | 220 | 185 | 145 | 122 | 4-18 |

| 80 | 3'' | 250 | 200 | 160 | 138 | 8-18 |

| 100 | 4'' | 280 | 220 | 180 | 158 | 8-18 |

| 125 | 5'' | 320 | 250 | 210 | 188 | 8-18 |

| 150 | 6'' | 360 | 285 | 240 | 212 | 8-22 |

| 200 | 8'' | 400 | 340 | 295 | 268 | 12-22 |